18th Edition has been published and it contains mention of the Arc Fault Detection Device (AFDD), aka the Arc Fault Circuit Interrupter (AFCI) if you’re reading this Stateside. These things are still a rarity here in the UK, but I’ve been given one to put through its paces!

So, AFDD’s have made it into ‘the big blue book’. I’ve been trying to get hold of one of these via the wholesaler route for some time but without much success even if I’m armed with a part code, and there doesn’t seem to be a great deal of information out there about what these things are and how they work, even though they’re popular in America, Australia and with several of our European neighbours.

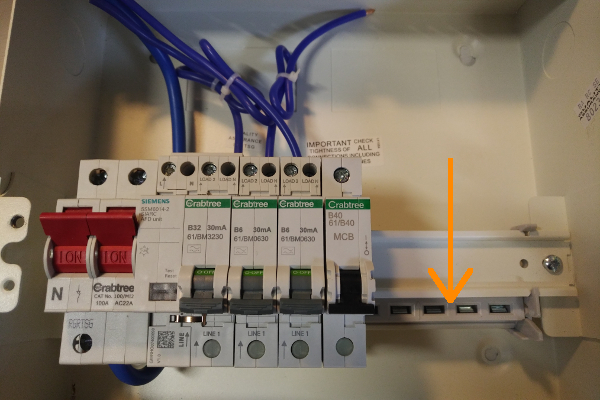

But, pictured here is the Crabtree model, and I must thank my friends at Electrium, part of the Siemens group and the peeps behind such venerable British brands as Volex, Wylex, Appleby and of course Crabtree, because Electrium have generously provided me with their current AFDD offering for my entertainment and enjoyment to share with you today.

Much of what is covered in this article is available in video form on my YouTube channel where you can see this thing in arcing action…

…but for those who prefer the written word, let me continue by saying not only am I lucky enough to have my hands on one of these things, but I’m also lucky in the fact that this is not just any old AFDD: this Crabtree model is something of a market leader as it provides three-in-one circuit protection with overcurrent, earth fault leakage and arc fault detection, and yet it has a smaller footprint than the Eaton equivalent which is a third larger and takes up three fuseways instead of two, while the Schneider and Hager offerings, from what I’ve seen, are the same double-width size as this but lack the earth leakage element altogether.

Looking below at the Crabtree device, you may spot that we have two components mated together here. On the left is the arc fault detector, branded as Siemens in this case, but I’m told that if a Crabtree or Wylex part code is ordered the Siemens name will be removed for the UK market. On the right is a miniature RCBO which here is double-pole unlike many on the market. The two devices connect together for a rather clever and flexible solution.

I have it on good authority that this dual-width package will soon be shrunk into a single miniature RCBO form factor and that such a device is already on the German market, so the expectation is that by the time the wiring regs shifts its wording for AFDD’s from ‘recommended’ to ‘required’, then the market should be sporting three-in-one devices that fit into an existing fuseway, so hopefully we don’t all have to throw our hands in the air in exasperation at the size of consumer units of the future!

I need to mention one other design feature of this Crabtree product which is that it is part of the Starbreaker family. If you’re not familiar with Starbreaker, it’s a clever board design with a unique ‘safety busbar’ feature which means that if you’re performing some live diagnostic work, then the shock risk is much reduced as there is no copper busbar to be accidentally touched.

The Starbreaker plug-in busbar

The Starbreaker plug-in busbar

The Starbreaker protective devices have a tab protruding from their rear which simply plugs in to this busbar, reducing both installation time and the chance of a loose or misaligned connection at the busbar.

Wylex cage clamp (red) and Starbreaker tab (green)

Wylex cage clamp (red) and Starbreaker tab (green)

The advantage of the Starbreaker range for this AFDD product is that it’s an easy retrofit for existing boards; it just plugs in, again unlike the Schneider, Hager and Eaton rivals which would require removal of the existing busbar and some chopping and changing of it for their AFDD products to retrofit into place. If you want the traditional busbar format instead of the Starbreaker advantage, then the Wylex version is identical to this model and has the cage clamp.

Now that we’ve seen the physical form, let’s have a quick run-down on just what this thing is.

The Arc Fault Detection Device will interrupt the power upon detection of an electrical arc signature. Any electricians reading this will, I’m sure, have seen an arc; the flash of gas plasma created when electricity jumps an insulating gap. For those who haven’t, lightning is the same stuff doing the same thing in a much larger and highly impressive form.

An electrical arc is formed when there is a potential difference big enough to jump the insulating layer between two separated conductive parts. In most cases, that’ll be a simple loose connection where the copper wire isn’t in proper contact with the terminal and there is a small air gap between them. Air is an insulator, but the resistance of its insulation changes with temperature, humidity, airborne particles and other factors as I discussed in the video linked below.

Any insulator can be electrically overcome if you have a big enough ElectroMotive Force (EMF), so the larger the air gap between your conductive parts, the higher the voltage needed to break down the insulation of the air between those conductive parts to jump the gap. In the case of the UK domestic mains supply at around 230V, a millimetric air gap will likely result in a broken connection that can’t be jumped, but if conditions are favourable then an arc can form across the gap.

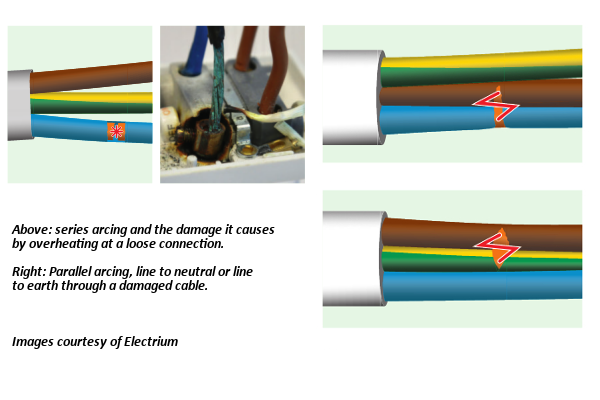

There are two forms of arcing: series and parallel. A series arc can form between two points on the same line such as where there is a nick in a single conductor or where it is improperly terminated. This kind of fault wouldn’t ordinarily cause a problem for the protective devices we already know and love as the kind of current being pulled across the arc is much less than the rated breaker or fuse value, so there’s no overcurrent event. It’s also not a fault to earth, so it won’t be troubling the RCD (GFCI) with this kind of in-circuit malfunction. A parallel arc is one which forms between conductors, i.e. line to neutral or line to earth. I’m not talking about a direct short as that would result in an overcurrent or earth leakage operation of the device, so again this is arcing where the circuit remains in operation, at least for some time, as the nature of the fault is such that it doesn’t breech the operational rating of a breaker or RCD, but nonetheless there’s a voltage jump across a compromised insulation layer. In the case of a parallel arc, it wouldn’t be down to a poor connection, more like a crushed, over-bent or physically damaged cable; something where the insulation has been squeezed down, gnawed at or chafed off.

Arc faults have their own dangers as they can cause a fire. At the point of the arcing we have a high-resistance, high-temperature joint, and as the temperature increases further, so does the resistance and we end up with this vicious cycle of resistance causing heat causing resistance causing heat and so on with the situation getting worse over time. Eventually, the local insulation and surrounding plastic parts will be damaged by overheating. If we’re lucky, the joint will simply fail and the damage will be uncovered when an electrician is called out to identify why the circuit is no longer functioning. If we’re unlucky, surrounding material may ignite and start a fire. Electric shower isolators are particularly prone to this problem in the UK as they use relatively thick 6-10mm cables which work loose in the isolator screw terminals and fizz away under a high current load until the isolator melts around the terminal. As I moaned about in another advice article on this site, I change out several of these things every year because of this kind of fault.

In theory then, the AFDD should detect such an arcing event and it should trip off to remove the power before things get too toasty. If called out to one of these when it trips, then my job would be to find that loose connection or damaged cable and that might be a tall order, especially on a circuit with a lot of points such as one serving socket outlets. I’d start by looking at each connection point for trapped insulation or a loose connection, probably just loose by fractions of a millimetre and likely with no tell-tale localised heat damage to act as my smoking gun because the AFDD will have clicked off before any heat damage occurs, after all, that is rather the point.

If I’m lucky, my inspection will locate the series arc location, or testing with an Ohmmeter/impedance tester might otherwise pick it up. If it's a parallel arc problem then I might identify it through insulation resistance testing or visual inspection where cabling is visible. If I’m unlucky, the fault will be in the supply wiring buried within the property, say a damaged cable or a moody hidden junction box that was improperly installed by a previous homeowner and which nobody else knows about and is now hidden under a laminate floor.

Tripping events with AFDD’s, especially in retrofit applications on older installations, could be a bit of a headache. Even if you think you’ve tested and traced a circuit fully, there may be some odd hidden spur branching off somewhere that you just haven’t spotted. Also, the fault may not be on the building cabling itself, it could be in an accessory such as a socket outlet with dust/debris inside or water ingress into an external luminaire, it could be a loose connection in a plugtop, a damaged appliance flex or inside the appliance at the cord grip, termination point or switch.

The AFDD is limited to monitoring the distribution wiring, so if you plug in a faulty electrical appliance, say with dry joints on the soldering, arcing may occur within the appliance, but if the arcing is isolated from the mains input, such as when it’s on the secondary side of a transformer or after an optoisolator, then the AFDD won’t detect it.

The way I see it, installing these into new builds or rewires where you know the wiring routes and can trust your work may not be so bad, but retrofit into older installations with existing wiring and aged appliances could be problematic. If a later revision of the regs insists on these for the retrofit market, I would personally consider pulling CU upgrades from my services portfolio, or I would put some wording into my terms and conditions to limit my liability.

If I turn up to a tripped AFDD, I should see some kind of visual indicator for an arc fault: a flashing yellow LED in the case of this SIEMENS model. If it shows a normal operational indicator light when powered back up, then that means the device wasn’t turned off by an arc event, so it’s down to the usual suspects that trouble RCBO’s, i.e. an overload or earth leakage event, and normal faultfinding rules apply. Hint: if it goes BANG when turned on, then it’s an overcurrent fault!

Of course, these devices mean yet another label to add to our consumer units or distribution boards to show the function of the visual indicator which varies between manufacturers. While the SIEMENS model used here on the Crabtree and Wylex ranges have a red light for 'status normal', the Eaton model has a green light. I suspect the Eaton would show red for an arc fault alarm, but I haven't seen it in action. A shame the colours couldn't have been standardised in some way to prevent sparkies of the future having to search what the indicator is showing on any model of AFDD they're unfamiliar with if the label happens to be absent!

The reset button on the AFDD also acts as a test button and trips the associated RCBO, and of course the RCBO has its own trip test function. While the RCBO test button is little more than a test of the mechanics, the AFDD test button, I imagine, instructs the electronics within the AFDD to trip the RCBO as though an arc fault has occurred. If the AFDD test button doesn’t work, then there’s potentially a problem with the electronic brain within the thing.

When installing such a device, the RCD test notice specified in 18th Edition under regulation 514.12.2 would also apply to AFDD equipment and instructs the homeowner to periodically test the electronics of the device through the use of the TEST button. Note however that in 18th Edition, the notice has changed the frequency of recommended testing from quarterly to bi-annually, so although you now have another device to recommend to your clients to test, at least it’s now once every six months instead of every three.

This is all very well, but what about natural arcs? By that, I mean arcs formed on electric motors or the action of any mechanical switch, relay or contactor. We’ve all seen arcs and sparks being spat out by drill motors and the like in normal operation, so what’s to stop the power being canned by one of these things whenever you want to undertake a spot of DIY or turn on the lights?

Some rather large and bright arcing visible through the vent on my (failing) drill

Some rather large and bright arcing visible through the vent on my (failing) drill

Unlike a breaker or RCD, the AFDD is not a basic electromechanical device, there are some clever electronics within and those electronics are looking for a telltale arc signature. Not just any old arc will trigger this device, it knows about natural arcs and it will ignore them. The signature of a loose connection arc is an altogether different beast and it induces a different interference pattern on the AC waveform which will actuate the device.

When it comes to arc fault detection, it’s applied per-circuit like overcurrent protection, but perhaps unlike RCD or surge protection which are often applied to a group of circuits or to the installation as a whole. This means you wouldn’t use one AFDD per installation, but rather one per circuit and although 18th Edition only recommends their use, it doesn’t specify on what kind of circuits they may be used on, so I guess higher current applications such as power distribution and electric showers may benefit more than, say, lighting circuits, as those circuits with more points or with a higher current carrying capacity may be more prone to suffering from an arcing issue.

You may wonder how they’d cope on a socket ring main circuit as a break in a single conductor won’t allow a series arc to form: the current has an alternative path down the unbroken ring leg. But then if there isn’t an arc, there isn’t any danger from an arc, so the device doesn’t need to function in that scenario. That said, a series arc could form if there are breaks in both legs, or where two poorly terminated wires meet at an accessory (with current being pulled through the accessory) or on spur wiring. Parallel arcs could form anywhere on a ring circuit of course, so this device does have a place on ring wiring.

So, there we have it, some questions answered on the AFDD, how it works and what it does. Although they’re a bit new and unknown on the UK market at the time of writing, we’ll probably soon see them becoming more commonplace, especially as the form factor shrinks and pricing starts to drop through economies of scale. What headaches they may cause on installation and faultfinding for the likes of me remains to be seen however!

Update, December 2020

Doesn't time fly? It feels like just a few minutes ago that we were reading the above article from July 2018 and now by this sentence it's two and a half years later! Oh, and with that comes not one, not two but THREE new videos showing the mythical three-in-one AFDD mentioned in the above text actually being applied to a retrofit installation complete with some robust analysis of how well these things operate, what tests are required when faultfinding, how I made a test instrument to prove operation and the final certification of the bugger! As is usual with my later video content, I'm not as polite as I was in 2018, so ruddy language applies. But come on, who else has this much information on AFDDs in the UK from an electrician's point of view at this time? Go use that link at the bottom of the page to buy me a gin Martini for goodness sake. Shaken, not stirred.