Got a plastic consumer unit (fuse box)? Been told you need to change it for a metal one? Well, unless your plastic enclosure is demonstrably damaged, dangerous or inadequate, then the mere fact it is plastic does not warrant a replacement and neither should it show up as a failure item on a condition report.

I had a call from a worried lady in Dorset regarding an electrician who, while performing major work on her house as part of a building project, told her that her Consumer Unit (CU) "wasn’t compliant with regulations" because it was made of plastic. Seeing as she had appointed British Gas to replace the CU just a few months ago in 2015, she was concerned that the work she had paid for would now need to be repeated at additional cost.

Although the regulations have recently changed to ensure all new consumer units installed from January 2016 are made of steel, as far as I can see there are three reasons why the sparky on site may have said the existing plastic CU was not compliant for continued operation…

- He genuinely believes the plastic consumer unit needs to be replaced with a metal one in order that the new circuits he is installing can be signed off as being compliant with the latest regulations.

- He’s hoping to drum up extra business for himself by replacing the plastic CU with a metal equivalent.

- He’s just mentioning it as an aside and has no intention of performing any work on the CU.

Whichever of the above is true, this electrician has acted incorrectly and I’ll take each scenario in turn to explain why…

Scenario 1:

BS7671 (IET Wiring Regulations) Amendment 3 is only mandatory for new electrical installation work designed from 1st July 2015, or in the case of consumer units, from 1st January 2016. Any electrical work that was designed and installed to Amendment 2 or earlier remains valid because it complies with the standards of its time, that is assuming it was properly installed to the standards of its time and wasn’t chucked in by a cowboy, or hasn't degraded and otherwise shows no signs of wear, damage, improper modifications or overheating. As British Gas was the installer in this case, we can hopefully assume they knew what they were doing and they signed the job off as being compliant by providing an Electrical Installation Certificate (EIC).

As we’re now into 2016, the electrician on site today would have to ensure all of his new work is compliant with the latest regulations, but he does not have to upgrade older, functional and safely operational parts of the installation, including the consumer unit, even if he is running in new circuits from it.

If the existing CU is particularly old, damaged, shows signs of overheating or contains inadequate protective devices, then an upgrade would be required, but where a CU has recently been professionally installed and is compliant all the way up to 17th Edition Amendment 2, then suggesting a replacement, if that is what is happening here, is clearly ridiculous. The goalposts may have shifted regarding new installations, but that doesn't mean anything older has suddenly become unsafe and inadequate overnight.

If this sparky is troubled by there being an Amendment 2 CU at the origin of his new circuits, then he can cover himself by mentioning on his certificate that the CU is an Amendment 2 distribution board under the ‘Comments on Existing Installation’ section, although I myself wouldn’t bother as it would be pointing out the obvious to anyone who is qualified enough to disseminate the information contained on a cert. Neither would I list it in the ‘Details of Departures from BS7671’ section even if I am running in a new circuit where its origin is from an older CU because although my certificate would cover all the elements of my new circuit, including the protective device, it would not include the CU enclosure itself which someone else has previously installed and certified as being compliant at the time that body of work was undertaken.

In short, whatever material the consumer unit enclosure is made out of has nothing to do with the current electrician on site as he didn't install it, so he won’t be taking the legal liability for it when he signs off his certificate. British Gas have already done that, and at the time they did it plastic consumer units were perfectly acceptable, so everyone’s happy and the universe remains in balance!

My concern with scenario 1 is that if he really believes he should be changing out an Amendment 2 board in order to sign off new circuits, then he may not understand the regulations fully enough to be trusted to work unsupervised on electrical installations. It makes me wonder if he has any other basic ‘knowledge gaps’.

Scenario 2:

If he’s prepared to change out a 2015 Amendment 2 CU that was installed and certified by a professional company, then he’s either daft or chancing his arm. It goes without saying that if he knows full well that the CU doesn’t need changing, or if he insists it is necessary even after he’s been shown the error of his ways, then he isn’t someone who should be working on anybody’s electrical installation and he should swiftly be shown the door.

Scenario 3:

It may be that he’s just mentioned the fact to the homeowner that her Amendment 2 board is not compliant with Amendment 3, but the effect of this is to have worried the homeowner enough for her to spend time searching for information and going around in circles with a hopeless British Gas call centre about the longevity of the installation work they recently performed. After coming across my website and speaking with me on the matter, I hope I’ve put her fears to rest, but no tradesperson should be putting fear into their client in the first place unless there are serious and immediate issues which urgently need addressing to prevent danger. This electrician is at liberty to provide information and make comments, but he should have told her it’s fine, it doesn’t need changing and that British Gas haven’t short changed her unless he can demonstrate that the quality of their installation work is substandard or there is a serious issue with the existing CU as installed. The simple fact of it being made of plastic is not an issue in of itself.

Old consumer units, including rewirable fuse boxes, do not need to be changed so long as they still provide adequate protection, even if they are plastic, although in the case of rewirable fuse boxes it is highly recommended that they are changed for a modern consumer unit as circuit breakers offer faster reaction times and more convenience when it comes to resetting after a trip, and a modern CU will have RCD’s for preventing electric shock.

Indeed, it’s the requirement for RCD’s which causes most headaches for those with old consumer units/fuse boxes. For compliance with current regulations, new circuits installed today would require RCD protection in order to be signed off. Your existing consumer unit may have RCD protection on all circuits, on some circuits or not at all, and depending on the extent of any alterations you’re making to your electrical installation it may well be the best option to have your distribution board upgraded if it is old so that you have full RCD protection at the source.

Anyone recommending you have your consumer unit upgraded should be able to give demonstrable reasons why it is needed. Merely saying that an existing one is plastic and they now all have to be metal isn’t true as the regulations don’t apply retrospectively. You don’t need to update an old installation for the sake of making it compliant with the latest regs, only any new additions or alterations made to that electrical installation should be undertaken to the latest standards. It says as much at the beginning of the Regs book where, under Note by the Health and Safety Executive, it states "Existing installations may have been designed and installed to conform to the standards set by earlier editions of BS7671 or the IEE Wiring Regulations. This does not mean that they will fail to achieve conformity with the relevant parts of the Electricity at Work Regulations 1989." Regulation 651.2 which appeared from 2018 also specifically permits older installations to pass inspections; there's no requirement for an older installation to fully meet the latest standards.

Where the protective devices installed within a CU are already up to par, as would be the case in this lady's Amendment 2 board, there’s no reason to change the CU enclosure from plastic to metal unless there is an obvious benefit for going to that cost and effort, such as if the old CU is too small to accommodate new circuits and something larger is required or if the old CU has been damaged and has a crack or hole exposing live parts or shows evidence of overheating. These are examples of where a new enclosure may be employed without necessarily changing the internals (breakers/RCD’s/main switch), and any new enclosure installed today would now have to be metal if fitted in a domestic property.

Even if the installer insists that his shiny new circuit cannot be run from an older enclosure, perhaps because it's too small, obsolete or otherwise just plain unsuitable, plastic or not, then a more cost effective option for the customer could be to have the installer fit a secondary metal consumer unit just to serve the new circuit. This can be signed off and certified without any effect on the existing older installation. This keeps the installer happy because they're not touching the existing electrics, so they take no responsibility for it. This is common for older installations where the likes of electric showers, EV chargers or solar PV installations have been added on.

Incidentally, the need for metal enclosures only applies to dwellings, so commercial installations or a detached shed/garage can still have a plastic CU installed. Also, anyone with plastic CU’s still on the shelf can continue to install them in dwellings so long as they enclose them in a metal box compliant with Regulations 421.1.201 and 132.12.

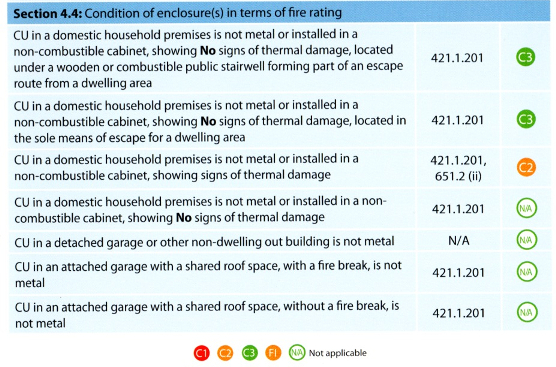

All this also applies to anyone who has had an Electrical Installation Condition Report (EICR) performed on an existing installation where the report has listed a C1/C2/C3 condition just because the consumer unit enclosure is made of plastic. C1 means 'immediate danger' and that would only apply if the enclosure is damaged or missing covers and exposing live parts. C2 is 'dangerous in the event of a fault' and wouldn’t apply unless the wiring and devices within the CU are in such a poor state they’re likely to cause a fire that the CU may not be able to contain. If the wiring within the CU is good, then at the very most a CU enclosure may be given a C3 coding (improvement recommended) just for the fact it is made of plastic, but C3 issues are like vehicle M.O.T. advisories and do not fail a report. If you’ve had an EICR performed and it’s branded your installation as unsatisfactory because a C1 or C2 has been issued just because the CU is plastic, then the person performing the inspection is either a scammer trying to flog you an unnecessary upgrade or they don’t know how to properly perform an EICR.

You don’t have to take my word for it though. Here’s what the charity Electrical Safety First recommend in Best Practice Guide 4…

A C3 should be issued…

“For inspections carried out after 1st January 2016: Presence of a consumer unit or similar switchgear made from combustible material (e.g. plastic) that is not inside a non-combustible enclosure and which is:

• Located under a wooden staircase, or

• within a sole route of escape from the premises

(Note: If unsatisfactory connections are found during inspection, this would warrant a code C2 classification to be recorded)”

The guide goes on to state that where plastic enclosures are not located under wooden stairs or in a sole route of escape then it does not require a code and would not appear on the report. This is backed up in the NAPIT Codebreakers book:

NAPIT Codebreakers - C3 only if under wooden stairs/in an escape route

If you feel that someone has been spinning you a line about your plastic consumer unit and you suspect they’re trying to screw you for cash to right an issue that isn’t really an issue, then do the following:

Go to the Electrical Competent Person website and look up the name of the sparky. If they don’t appear on this database then they are not accredited, so pull the plug on them and seek someone else to perform the work.

If they are listed then it will tell you which Competent Person Scheme (CPS) they are registered with; NICEIC in my case at the time of writing. Look up the website for that CPS and you’ll find a customer enquiry number. Call them and tell them you believe one of their members is giving you duff advice. Leave the CPS to question the sparky for his justification for wanting to change your CU and if their only reason is “because it’s plastic”, the CPS will no doubt tell them that on its own, this is no justification.

A lookup on the Electrical Competent Person database will show which scheme, if any, your chosen installer is affiliated with.

Just to add, if someone is changing your consumer unit, they should perform full electrical inspection and testing (EICR) on the entire installation to ensure there are no pre-existing issues they need to be aware of or need to correct beforehand. This body of work will itself take about half a day on your average semi-detached to be done properly. I mention this because I had a caller tell me their installer was insisting their plastic consumer unit had to be upgraded to a metal enclosure just for 'compliance', but then telling the client that once they had upgraded it then it may highlight 'other issues'. No no no! Any other issues must be uncovered beforehand, otherwise what are they going to do when they find they can't switch the new consumer unit on because the RCD won't operate? It's not like they can just roll-back the installation to get the juice flowing and if there are serious pre-existing faults preventing it from working, then the time to put right or the budget to pay for it may not have been accounted for. In the meantime, the freezer is defrosting and night is drawing in!

Personally I’m not a fan of metal consumer units. Plastic versions were easier to work with, tended to be cheaper, naturally provided a layer of insulation and they were only dangerous if installed or worked on by the inept. Metal enclosures fitted by cowboys or morons are likely to be just as dangerous even if they do have a better chance of containing a fire. With all the dodgy DIY-ers and cash-in-hand cowboys out there, it’s only a matter of time before some idiot installs a metal CU and neglects to connect the main earth leaving a big conductive box humming on the wall.

Update 09/08/18.

The 18th Edition wiring regulations have now been published and supersede 17th Edition Amendment 3, but the requirement for metal consumer units on new installations remains and there has been no change in the regulations requiring older installations to be updated simply based on the material the enclosure is constructed from. The opposite in fact, as Regulation 651.2 was introduced with 18th Edition which aims to clear up the issue of passing older installations on inspections by permitting such to exist so long as they remain free of defects. There will never be a change in the wiring regulations mandating older installations be brought to up to the latest standard for reasons explained in another article on my site.

I had a lady contact me today because she has received an EICR which had noted the presence of a plastic consumer unit (not in an escape route) and had been advised by the person compiling the report that it should be changed or she may be held legally liable for any fire incidents afterwards. On the face of it, this is nonsense. I haven't seen the installation or the report, but here are some facts:

- If the inspector has done their inspection and testing properly, then they should have confirmed on the report that there are no issues at the consumer unit such as loose connections, non-approved modifications, unsuitable fitted equipment, incorrect busbar fitting, exposed live parts, thermal damage etc. If they're confirming none of these conditions exist, then the legal iability rests with them, not the homeowner. If the installation has passed for safety for everything other than the material of the consumer unit enclosure, then what's the fire risk?

- Only if there is a demonstrable failing of the plastic consumer unit such as a cracked case, missing parts, holes, thermal damage etc. would it then result in the recommendation of repair/replacement of the enclosure depending on the severity of the problem. If the problem is severe enough that danger is, or could be, present, then the homeowner must be informed and they then accept the liability if they fail to act on that advice, but the inspector must be able to demonstrate evidence of the problem or justify what the risk is.

An inspector can't have it both ways - they can't tick the boxes on the report that says everything is okay, then recommend you change the consumer unit before it bursts into flames! Either there's a demonstrable risk of fire because of the way the consumer unit has been installed or maintained, or it's in a serviceable condition and is not at risk of spontaneous combustion any time soon. There has to be more detail about why it's a fire risk, and something else on the report to show the cause of this risk, i.e. an improperly modified busbar, an underrated main switch, thermal damage from a loose connection at the tails etc. These items would show up on a report in their own right and it may be possible to put them right without resorting to the baby and bathwater solution of replacing the whole damn thing. If the inspector cannot point to any other reason for making the change, then the liability for the ongoing safety rests with them as they're the expert stating they can't point to any smoking gun (or smoking circuit breaker) therefore there should be no immediate risk of fire.

The whole metal consumer unit thing is a gift for cowboy installers who can blag to unsuspecting clients that unnecessary remedial work needs doing. Ironically, the effect is often that a perfectly serviceable plastic CU is changed for a poorly fitted metal one and it doesn't matter what the bloody box is made of if it's left full of air holes and loose connections: the fire will find a way out.

On the subject of substandard EICRs is this video of mine where I pull apart the paperwork of an idiot. Appropriately strong language applies. This can also be found in article form here. Another example of someone being short-changed about plastic consumer units can be found here.